PREDICTIVE MAINTENANCE

MAINTENANCE

PREDICTIVE

Advanced inspection technology without interruptions.

Design of Predictive Maintenance Systems

The design of predictive maintenance systems with thermographic inspection windows and ultrasound allows for the implementation of proactive non-contact monitoring strategies that improve safety, reduce the risk of electrical failure and optimize operational continuity in critical facilities.

These solutions are designed to facilitate safe, accurate and fast periodic inspections.

Phases of the Design Process

Significant reduction of electrical risk and personnel exposure.

Elimination of unscheduled shutdowns due to avoidable failures.

Operational savings due to reduced maintenance.

Traceability, documentary evidence and regulatory compliance.

Early detection of thermal, mechanical or insulation failures

DESIGN OBJECTIVES:

Intelligent Infrastructure for Proactive Maintenance

SYSTEM COMPONENTS

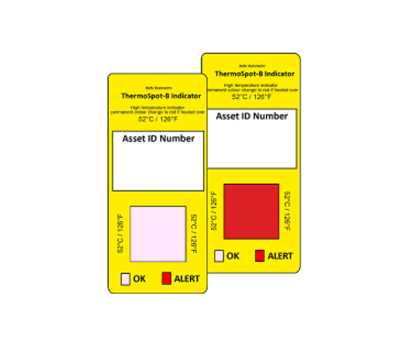

Smart labeling:

Identification of each inspection point for traceability and control.

Predictive management software:

Integration with maintenance platforms to schedule and record trends.

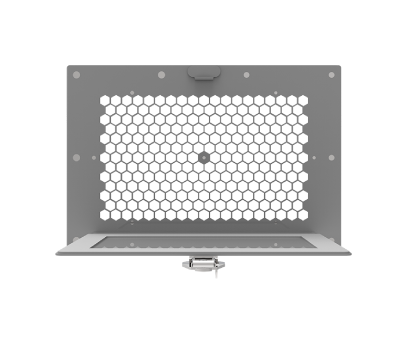

Acoustic windows for ultrasound:

They allow the inspection of partial discharges, corona effect or loose connections by means of ultrasonic equipment without opening cabinets.

Thermographic windows:

Inspection ports with germanium glass or IR polymer covers for viewing hot spots on busbars, breakers, contacts, etc.